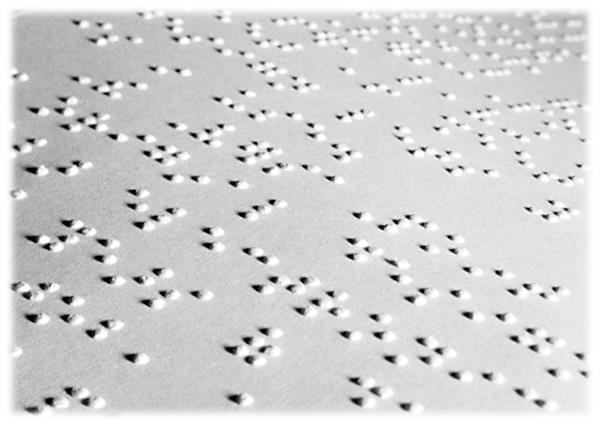

The term quality is used to describe something as being superior or non-inferior to that of its competitors. Braille embosser manufacturers often use the term quality to describe the braille that their embossers are able to produce. The question is, who actually offers superior braille, and at an affordable price? And how do you identify good quality braille production as a sighted person?

For visually impaired individuals in which are braille literate, it is easy to depict if a particular braille embosser produces "quality" braille or not, because it is just a matter of beginning to read. However, sighted people rely on the visual appearance of braille dots in order to decide which produces the best braille. Some sighted individuals are trained to read braille by sight, however many persons who may be on the market to purchase a braille embosser do not always know what to look for. Therefore, this article may be used as a guide for sighted people to identify quality braille production.

What to look for

What to look for

For the sake of this article, by quality braille we mean braille dots that are easily read by a braille reader, and contains a shape that will hold for many years.

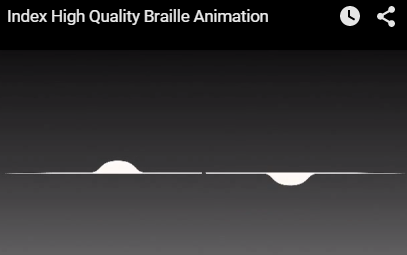

The single most important physical quality of braille is the form the dots take when produced. A

rounded dome shape is the ideal form for braille dots. As a sighted person you may look at the paper at eye level in order to see this dome-like shape. The dome shape can only be produced with braille technology in which presses and traps the paper from every angle equally, and just enough to create the rounded shape without breaking through the paper. This braille dot form is not only the most comfortable for a braille reader to read, but also holds and won't wear with age. - (After being read numerous times, the pressure from reading the braille with your finger can cause the braille dots to loose their shape over time. For this reason, it is additionally important that this dome-like shape is present to ensure a longer lifespan for the braille dots and to ultimately hold the claim for offering quality braille.)

Alternative methods or braille dot shapes unfortunately can be too rough by touch and therefore uncomfortable or even confusing to read. Furthermore, not able to hold its dot shape for any lengthier amounts of time either.

Why Index Braille?

Why Index Braille?

We believe in our claim for quality braille. The dots are comfortable to read and perfectly shaped. Even when printing double-sided (

interpoint) braille, every dot is crystal clear.

The Index Braille embossers have a higher price performance ratio than any other Braille embosser brand. This means that a braille embosser from Index Braille is more durable, has a faster embossing speed, more useful features and superior braille technology; all provided in a single embosser. And compared to competitor products; still capable of maintaining the same price range and offering quality braille dots that won't wear with age.

Watch this video to see how we are able to produce perfectly rounded dome shaped braille dots!

If you are curious just how great our braille we produce is,

Request a braille sample. You even have the opportunity to submit your own content for us to print using

idB and we will ship it to you!

-Something to keep in mind is that the paper being used is important to ensure a braille embosser can reach its full potential. The standard recommended size (thickness) of the paper used to emboss braille is 120-180 g/m2. Additionally the fiber counts and material used are other details to keep in mind when purchasing paper for your braille embosser.